Tales from the Scales: ScrapWare Blog

What’s happening in the world of scrap recycling—and what’s around the corner?

Get the latest industry news, updates, and insights here. We’ve assembled original and existing content from a variety of reputable sources. Check back often to stay in the loop!

Four Ways Scrapware’s Ledger Software for Scrap Metal Recyclers Can Boost Your Scrap Yard’s Profitability

Most scrap yard owners rely on tools in standard accounting software to process the financial functions of their business—purchases, sales, and payroll. For scrap metal recyclers, using the Ledger Interface Module in ScrapWare software can turn this routine task...

Recycling Heroes Honored for Global Recycling Day 2024

Champions of recycling from around the world were recognized as recycling heroes this year by the Global Recycling Foundation as it commemorated Global Recycling Day 2024. #RecyclingHeroes was the theme for this year’s annual event on March 18. Now, in its...

This Data Reporting Tool Can Help Your Yard Clean Up

In the scrap metal recycling industry, data is king. Keeping track of incoming material, inventory, shipments, and prices can help you make informed decisions to increase profitability. But how do you quickly get this business intelligence into the hands of your key...

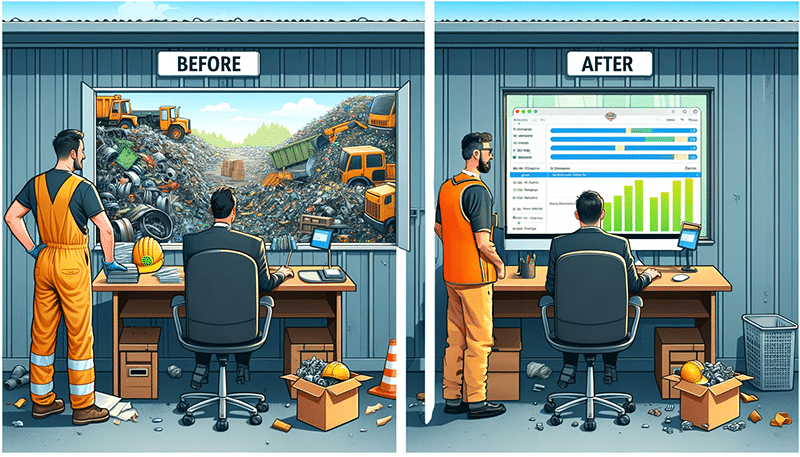

How to Increase Your Scrapyard’s Profitability with Bottom-Line Boosting Reports

Too often, we hear stories of scrap yard owners who spend their days overwhelmed by operational inefficiencies. From scrap metal coming in with no easy way to track the volume, type of materials, or pricing data to questions about dispatch decisions, many rely on gut...

A Shiny Solution: How Jewelers Are Embracing Precious Metal Recycling to Boost Sustainability and Profits

Recycling of precious metals to create jewelry has taken a step into the limelight with the announcement by jeweler Pandora that it soon will use only recycled silver and gold in its jewelry. Other jewelers may be following suit as consumers are looking for...

Revolutionizing the Recycling Game: How the Scrap Metal Industry Became the Longtime Leader in Innovation

The focus on clean energy and the demand for recycled materials are growing environmental concerns. Clean energy requires extensive use of metals like copper. Manufacturers and builders increasingly seek secondary raw materials, which are recycled...

Regulatory Compliance Simplified with Industry-Specific Scrap Metal Recycling Software

Regulatory compliance is essential for any business operating in today’s economy. The ability to comply with various federal, state, and local laws–and document that compliance– is needed for business continuity. The scrap metal recycling...

Unlocking the Potential: Latest Advances in Circular Economy

The recycling industry is being joined by government agencies, business, and environmental interest groups in moving toward a circular economy, an effort to both enhance the environment and create value. While the recycling industry has been at the forefront of...