There was a time in the scrap metal recycling industry when incoming material was sorted by hand, tickets were written by hand, and bookkeeping was done by hand (with perhaps the help of a calculator.) Today, the scrap metal recycling industry is on the cutting edge of innovation, utilizing new technologies to process more material in a more efficient, more accurate and faster manner. Adoption of technology in the recycling industry has been employed to increase recycling rates, keep up with changing materials and products entering the waste stream and improve profitability for scrap metal recyclers.

Outlined below are some examples of how technology is impacting the recycling industry.

Sorting and Processing Material

A host of technological advances in recent years have been put in place in scrap metal recycling yards to help sort and process material. This technology has been implemented to speed up the task of sorting everything by hand, to address the changing nature of complexity of materials now in the waste stream and the complexity of products such as electronics. The goal has been to speed up processing and increase the amount of recycled material. Overall, better sorting of incoming scrap can help companies produce “cleaner” batches of material for onward processing.

Today, sensors and sorting machines do much of the work today that was at one time done by hand. Companies are experimenting with x-ray technology and infrared scanning to sort non-magnetic metals. Laser object detection (LOD) is being used to identify non-metals so they can be removed before processing. Laser technology for scrap metal processing can result in significant savings by retaining more recyclable material in a faster period.

The use of XRF, or x-ray fluorescence, creates immense value for scrap metal recyclers. This technology can positively identify numerous alloy grades and rapidly analyze their chemical composition at material transfer points and thus help guarantee the quality of the product. Handheld XRF analyzers provide accurate and reliable material identification. These and other handheld devices using x-rays and/or lasers detect metals, alloys and contaminants. They can even be equipped with technology to improve sorting by identifying the chemical composition of most scrap material in a few seconds. This is an important technological development because there are many different types and grades of metals today than there were in the past. Subsequently, more sophisticated processes are needed to identify the material.

The volume of electronic devices entering the waste stream poses additional challenges requiring new technology. Although these devices are made with precious metals, they contain such minute amounts that recovering them is not cost effective without new technology. The separation of e-waste devices requires more technologically advanced and sophisticated equipment. Some large recyclers today are using infrared and x-ray technology to sort out valuable metals in the e-waste stream.

Software

Industry-specific software designed for scrap metal recyclers implements many technological advances that have improved many facets of a recycler’s operations. Overall, software helps companies maximize efficiency, while helping improve integration and productivity.

Here are just a few areas software has enabled technological advances for recycling companies.

- Routing – Routing software for scrap metal recyclers has enabled them to optimize their truck fleet routing. It can arrange driving routes to optimize the use of resources in the most productive way possible. Some fleet and container technology allows customer and vendor information to be collected, helping to improve quality of service. Utilizing this technology decreases energy consumption, increases efficiency, and improves client interaction.

- Inventory management – Software programs can help scrap metal recycling companies manage, analyze and optimize their inventory flow. For most companies, this is one of the most significant elements of profitability. The right software program allows a recycler to know what material is on hand, at what location, at any given time. It will indicate the price or value of the material, given its stage of processing and what is available for sale. A scrap metal recycling software system inventory module should allow you to: print and scan barcodes, define categories of material and track its pricing, allow for accurately entering data and integrate with other modules of the software for even greater efficiencies.

- Anti-theft compliance – A good recycling software will utilize technology to facilitate accurate and complete compliance with state and local anti-theft laws. Scrap metal recyclers can use technology such as cameras, digital signature and thumbprint capture pads and other scrap yard hardware that will interface with programs that create reports and can be uploaded to the authorities for compliance.

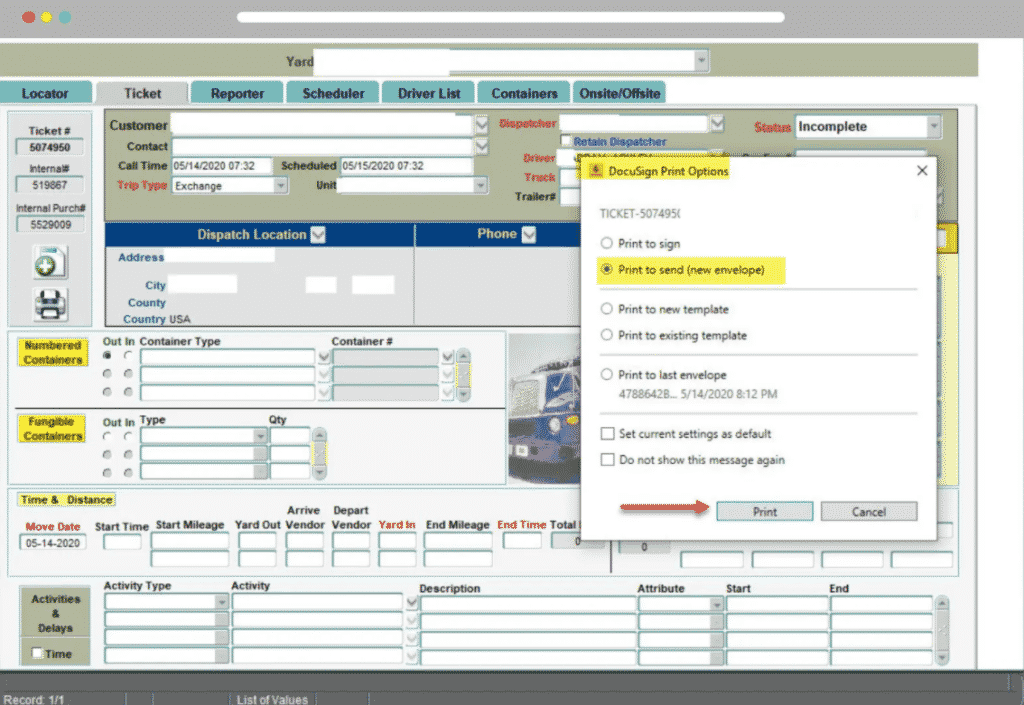

- Document signing – A premium scrap metal recycling software will allow companies to obtain digital signatures instead of relying on outdated paper documents. ScrapWare Corporation, which provides software to the scrap metal recycling industry, last year teamed up with DocuSign, the national leader in e-signatures, to make this technology available to its customers. ScrapWare’s e-signature product, ScrapScribe™, is technology that will streamline the business process, reduce user errors that can occur with paper documents, and remove bottlenecks associated with moving pieces of paper. ScrapScribe increases security and flexibility when obtaining signatures. This proprietary system facilitates e-signatures throughout all aspects of a company’s business and enables users to seamlessly send ScrapWare documents to DocuSign for signature. This includes dispatch tickets, purchase quotes, purchase contracts, packing lists and more. Documents can be easily viewed on any device and can be printed at any time, whenever necessary.

What the future holds

Looking into the future, scrap metal recyclers can anticipate more complicated products and materials entering their waste stream, but with more intelligent product design. Manufacturers of consumer goods like electronics are looking at innovative ways to improve product design so that when an item is at the end of its useful life, it can more adequately be broken down and disassembled for easier recycling.

Finally, the use of artificial intelligence (AI) is expected to play a larger role in the recycling industry. AI is now already being used at some larger solid waste services companies, where AI guided robots can pull recyclable materials from waste streams. In the future AI machines are expected to be able to recognize materials, trucks and even drivers with optical technology.

Recyclers and researchers are continuing to develop and implement more innovations to make recycling more efficient, more prevalent and less expensive. The result will be more recyclable material available to manufacturers and less material inadvertently ending up in a landfill. This translates to more profitability for scrap metal recyclers and more benefits for the environment.

ScrapWare Corp., of Rockville, MD, has been providing software to the scrap metal recycling industry for over 30 years. ScrapWare uses an Oracle database to provide a cloud-based software solution to manage all aspects of a recycling business. With numerous modules, extensive technical support, remote installation and online training, ScrapWare helps recycling companies with compliance, efficiency and profitability. Check out ScrapWare’s website, read the user testimonials, and see its offerings for your recycling software solution.